Topics Covered:

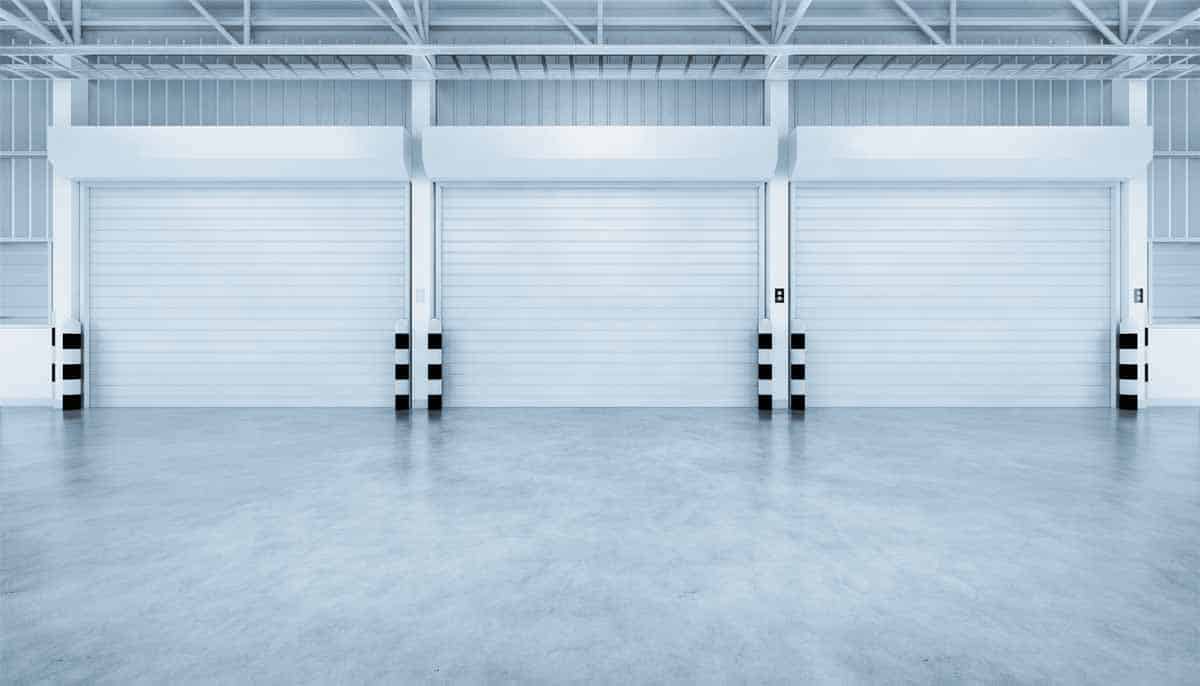

If your business relies on loading docks for shipping and receiving goods, then you already know that efficient logistics can make or break your daily operations. One crucial yet often overlooked aspect of this process is the loading dock door installation. A properly installed loading dock door doesn’t just offer security—it improves workflow, reduces downtime, and ultimately saves you money in the long run.

Streamlining Your Logistics for Faster Turnaround

One of the biggest advantages of having a well-installed loading dock door is the noticeable boost in logistics efficiency. When doors operate smoothly and reliably, trucks can be loaded and unloaded faster, minimizing delays. According to a survey by the Material Handling Institute, 60% of logistics managers cited avoidable warehouse delays as a primary cause of shipping issues.

Here’s how the right door installation helps you speed things up:

- Precise Alignment: Properly installed doors will align seamlessly with the dock levelers or ramps, allowing forklifts and workers to move quickly between the dock and the truck.

- Easy Operation: A loading dock door that opens and closes effortlessly means less time fiddling with stuck panels, broken tracks, or finicky openers.

- Reduced Downtime: Frequent repairs or door jams can bring warehouse operations to a screeching halt. A professionally installed door with quality components is less likely to fail, resulting in fewer work stoppages.

Time is money, especially in a bustling distribution center or warehouse environment. By streamlining your loading dock area with a door that’s installed correctly, you can enhance productivity and maximize the potential of your logistics team.

Safeguarding Your Inventory and Equipment

If you’re in the business of moving goods—whether it’s food, retail products, or raw materials—security is probably at the top of your list. A properly installed loading dock door serves as a robust first line of defense against theft, vandalism, or even wildlife intrusion. Here’s why that matters:

- Secure Seal: When doors are correctly fitted, there’s less gap for pests, rain, or unauthorized personnel to sneak in. Weatherstripping and tight alignments block drafts, critters, and other unwanted guests.

- Locking Mechanisms: Modern loading dock doors often come with advanced locks and electronic controls. A professional installation ensures these security features function as intended, keeping your assets safe.

- Sturdy Materials: High-quality steel or aluminum doors installed by experts can withstand forced entry attempts better than makeshift or poorly installed ones.

According to the National Retail Federation, organized retail crime costs businesses billions annually. Your loading dock is a prime target for such activity, making a secure door a vital part of any robust security strategy.

Maintaining Optimal Working Conditions and Energy Efficiency

In a warehouse or industrial setting, temperature control can make a significant difference in employee comfort and product safety (especially if you handle perishable goods). Proper loading dock door installation plays a key role in controlling indoor climate:

- Insulated Doors: If your operation needs to maintain certain temperatures—say, in a cold storage facility—insulated doors help keep the cold in (or out). This can have a substantial impact on your energy bills.

- Minimal Air Leaks: A correctly sealed loading dock door prevents heat exchange between the inside and outside, stabilizing internal temperatures. This is especially important in Raleigh’s hot, humid summers and cooler winters.

- Better Air Quality: Sealing off external elements also helps reduce dust, fumes, or pollutants that could compromise product quality and worker health.

The U.S. Department of Energy suggests that well-insulated and sealed doors in industrial settings can cut energy costs by up to 20%. That’s real money that could be reinvested back into your business.

Ensuring Employee Safety

Safety should always be a top priority. A poorly installed loading dock door can pose serious hazards, not just for equipment but for the people operating that equipment. Common dangers include doors that unexpectedly drop, misaligned tracks causing roller malfunction, or inadequate sensors failing to detect obstacles.

By contrast, a professionally installed door includes:

- Auto-Reverse Mechanism: Similar to residential garage doors, commercial doors can have sensors that detect if a person or object is in the doorway, preventing accidents.

- Safe Counterbalance Systems: Springs and cables under the right tension ensure that the door moves predictably, reducing the risk of a sudden, forceful slam.

- Durable Construction: Heavy industrial doors are built to withstand daily use. If installed incorrectly, their heavy weight can be a liability. Proper installation ensures they’re secure and less likely to fall off track.

According to the Occupational Safety and Health Administration (OSHA), thousands of injuries occur each year due to industrial door-related accidents. A reliable, well-installed door dramatically lowers that risk, helping you keep your workforce safe and your business OSHA-compliant.

Complying with Local and Federal Regulations

Speaking of OSHA, businesses operating in the U.S. must adhere to various regulations and codes related to workplace safety, especially in warehouse environments. Depending on your industry, you might also need to consider:

- Fire Safety Codes: Some commercial doors are required to have specific fire ratings, self-closing mechanisms, or specialized materials.

- Wind-Load Requirements: In storm-prone regions, doors might need to meet high wind-load standards for hurricane or tornado resistance.

- Energy Efficiency Standards: Certain state or federal programs may provide incentives or set requirements for energy-saving building components, including loading dock doors.

Professional installers keep up with these ever-evolving regulations. They’ll guide you toward doors that meet or exceed legal standards, reducing the risk of fines, insurance complications, or forced renovations down the line.

Common Pitfalls of DIY or Improper Installations

With so much on the line—from security to operational efficiency—it’s essential to avoid the temptation to cut corners with a DIY approach or by hiring an inexperienced team. Below are some common pitfalls we see when installations aren’t done by knowledgeable pros:

- Misaligned Tracks: Even a small miscalculation can lead to the door binding or scraping each time it’s used. This shortens its lifespan and increases the risk of sudden failure.

- Poor Weather Sealing: Gaps around the edges let in drafts, water, and pests—negating energy-saving benefits and damaging goods.

- Weak Attachment Points: If the door isn’t securely anchored to the surrounding building structure, it’s more vulnerable to stress, wind, and forced entry attempts.

- Incorrect Spring Tension: Springs under too much or too little tension can lead to door imbalances or sudden, dangerous releases of energy.

When you weigh the cost of potential downtime, damaged goods, or employee injuries, the investment in a proper installation becomes a no-brainer.

Selecting the Right Door for Your Business Needs

Not all loading dock doors are created equal. Depending on your industry and volume of shipments, you might need a specific type of door. Here are some options worth considering:

- Sectional Overhead Doors: These doors roll up in sections overhead. Great for warehouses needing good insulation and frequent use.

- Roll-Up Steel Doors: Common in high-security or tighter spaces, these doors roll into a coil above the opening and can be very space-efficient.

- High-Speed Doors: Designed for fast open/close cycles, ideal if you have temperature-sensitive goods or need quick logistics turnarounds.

- Fire-Rated Doors: Built with special materials to contain fires, often required in certain industries or if your facility handles hazardous materials.

Talk to a professional installer about your specific logistics, climate, and building layout. Their expertise can guide you to the perfect solution—one that balances cost, durability, and functionality.

The Importance of Professional Maintenance

Once you’ve got that door installed, don’t just ignore it until something goes wrong. Regular maintenance can add years to the life of your loading dock door and keep it functioning at peak efficiency. Here’s what maintenance typically involves:

- Lubricating Moving Parts: Rollers, hinges, springs, and tracks all benefit from proper lubrication.

- Checking Tension and Balance: Springs should be adjusted to ensure the door remains stable and safe.

- Inspecting Seals: Over time, weatherstripping can degrade. Replacing worn seals maintains energy efficiency and keeps out pests.

- Testing Safety Features: Auto-reverse mechanisms and photo-eye sensors should be checked regularly to prevent accidents.

Many businesses opt for annual or biannual service contracts. This preventive approach often costs far less than emergency repairs and significantly cuts the risk of prolonged downtime if a major component fails unexpectedly.

Quick Stats That Show the Impact

You might be wondering, “Is a proper loading dock door installation really worth all this fuss?” Here are a few numbers that paint a compelling picture:

- Warehouse Efficiency: A McKinsey & Company study found that improving dock efficiency can increase overall warehouse productivity by 10–30%.

- Energy Costs: According to the U.S. Energy Information Administration, businesses can shave 5–20% off their energy bills simply by ensuring doors and docks are correctly sealed and insulated.

- Accident Reduction: OSHA estimates that proper maintenance and modern safety features on industrial doors can cut accident rates by up to 25%.

These stats highlight the far-reaching benefits—from cost savings and enhanced safety to a smoother flow in daily operations.

Working with a Trusted Local Partner

If you’re here in Raleigh or the surrounding area, we’d love to be your go-to resource for loading dock door installations. At RJ Garage Door Services, we pride ourselves on:

- Customized Solutions: We don’t just sell a door and call it a day. We assess your facility, operations, and budget to recommend a door that’s truly right for you.

- Professional Installation: Our technicians are trained, certified, and experienced in everything from sectional overhead doors to high-speed roll-up doors.

- Transparent Pricing: No hidden fees or surprises. We provide detailed estimates and work with your schedule to minimize disruptions.

- Maintenance Plans: Need ongoing support? We offer routine tune-ups and emergency repair services to keep your door running at its best.

Because we’re a local business, we understand the specific challenges Raleigh companies face. From humid summers to the occasional tropical storm threat, we’ll ensure your loading dock door can handle it all.

Final Thoughts: Elevate Your Logistics Game

When you think about logistics, your mind might jump to managing inventory, scheduling trucks, or tracking shipments. However, the loading dock door installation itself is a foundational piece that directly impacts how smoothly everything else goes. A poorly installed or outdated door can be a bottleneck, a security risk, and a drain on resources. Conversely, a well-installed, properly maintained door can supercharge your efficiency, lower your costs, and keep employees safe.

At RJ Garage Door Services, we’ve seen firsthand how the right door can transform operations. Whether you manage a massive distribution center or a smaller local warehouse, investing in a quality door and professional installation yields major returns down the road.